Microtopping, also known as microcement or concrete microtopping, is a thin, polymer-modified cement coating that creates seamless floors and surfaces with remarkable durability. Applied in multiple ultra-thin layers—typically 2–3 mm total—this innovative material forms decorative concrete finishes that transform ordinary spaces into modern, sophisticated environments.

This concrete overlay blends Portland cement, fine aggregates, acrylic polymers, and pigments to produce a surface that’s both beautiful and built to last. As a microtopping material, it bonds directly over existing substrates such as concrete floors, tiles, and properly prepared wood, which means you can achieve stunning results without the expense and disruption of complete demolition.

Property owners and designers choose microtopping flooring for its continuous, grout-free appearance that works beautifully in kitchens, bathrooms, retail spaces, and lobbies. This versatile system sits between traditional cement overlays and resin systems, delivering the sophisticated look of polished concrete with significantly less thickness and installation complexity.

When professionally installed and properly sealed, microtopping resists stains and abrasion while cleaning easily with pH-neutral cleaners. With proper maintenance, these surfaces commonly deliver lifespans ranging from 15 to 25 years, depending on the specific system used, substrate condition, and ongoing care.

Key Takeaways

- Microtopping is a thin, polymer-modified cement coating used for seamless floors and surfaces

- It combines cement, fine aggregates, polymers, and pigments to create decorative concrete finishes

- Microtopping material can be applied over concrete, tile, and prepared wood, significantly limiting demolition needs

- The finish mimics polished concrete with grout-free aesthetics and exceptional strength

- Proper sealing and maintenance can deliver 15–25 years of reliable service life

- As a concrete overlay, it often reduces project time, cost, and waste compared with full replacement

Table of Contents

What Is Microtopping

Microtopping is a decorative layer made from cement and polymer that creates a smooth, modern appearance across any surface. This advanced material can be mixed on site or comes pre-mixed, making it exceptionally practical for covering existing surfaces without extensive preparation work.

Key Components and Materials

The foundation of any quality microtopping system starts with Portland cement for structural strength and superior bonding to the substrate. Acrylic polymers and resins add the flexibility and crack resistance that make these surfaces so durable in real-world conditions.

Fine sand and aggregates control the final texture, allowing installers to achieve anything from mirror-smooth finishes to subtly textured surfaces that add visual interest. Mineral or liquid pigments offer an extensive range of colors that can match any design vision, while specialized additives and sealers provide additional performance benefits.

These additives include primers that ensure proper adhesion, waterproofing compounds for wet areas, and protective sealers that make surfaces easy to clean and maintain over time.

Typical Thickness and Application Substrates

Microtopping earns its name from its remarkably thin layer profile, usually measuring just 2–3 mm thick when fully applied. Despite being called “micro” for its minimal thickness, this material delivers full-strength performance that rivals much thicker traditional systems.

The secret lies in its exceptional bonding capabilities, which allow it to maintain level surfaces even when applied over existing substrates. This means you can achieve professional results over concrete, tile, masonry, and even properly prepared wood surfaces.

For wood floors, contractors typically install plywood subflooring first to ensure stability. Advanced systems can even work over mosaic or glazed tile with minimal demolition, making renovation projects faster and more cost-effective than traditional approaches.

Benefits of Microtopping for Residential and Commercial Spaces

Microtopping delivers a winning combination of durability and design flexibility that works equally well in homes and businesses. This versatile material offers the seamless appearance that modern spaces demand, along with practical benefits that make it a smart long-term investment.

Durability and Performance

Polymer-modified microtopping systems handle the demands of real-world use exceptionally well. These surfaces resist abrasion, impact, and heavy foot traffic while maintaining their appearance year after year. When properly sealed, they also provide excellent resistance to water and stain penetration.

Epoxy and acrylic formulations add chemical resistance that’s particularly valuable in commercial spaces where spills and harsh cleaning products are common. Many cement-based systems deliver 15–25+ years of reliable service, while advanced resin systems can exceed 30 years with superior crack resistance and performance.

Aesthetic Versatility and Customization

Designers can create virtually any look they envision, from sleek industrial finishes to warm, artisanal surfaces that feel handcrafted. The extensive color and texture palette allows for completely unique interiors that reflect personal style or brand identity.

The seamless finish makes spaces appear larger and more open by eliminating the visual breaks created by grout lines. Custom patterns, color blending, and specialized decorative techniques add distinctive character to both residential and commercial applications.

Practical Advantages

One of the most significant advantages is that microtopping can be applied over existing surfaces, which dramatically reduces project time, cost, and waste generation. The thin profile minimizes threshold buildup and often eliminates the need for expansion joints in smaller areas.

Daily maintenance couldn’t be simpler—regular sweeping and mopping with pH-neutral cleaners keeps surfaces looking fresh and new. Periodic resealing maintains protection and appearance based on traffic levels.

The environmental benefits are substantial too. Reduced demolition means less construction waste, and low-VOC formulations are readily available. Ready-mix systems minimize material waste while preserving durability, making microtopping an intelligent choice for environmentally conscious projects.

Types of Microtopping and Material Comparisons

Understanding the main categories helps buyers select the right microcement systems for their specific needs. Let’s explore the most common types, from simple powder mixes to sophisticated resin systems, and discuss where each option performs best.

Mono-Component Microcement

Mono-component microcement uses a straightforward powder-plus-water formula that includes integrated pigments and additives for improved workability. DIY enthusiasts and contractors appreciate this option because it’s simple to mix, features low VOC content, and cures relatively quickly.

This type works well for straightforward interior applications where budget is a primary concern. However, it may require additional sealer coats for optimal water resistance and longevity, and improper application can lead to cracking on substrates that experience movement.

Bi-Component Microcement

Bi-component systems combine cement powder with liquid polymer components, creating chemistry that significantly improves adhesion while adding flexibility, impact resistance, and water protection. This enhanced performance makes it ideal for floors and walls that experience slight movement or heavy wear patterns.

While mixing and surface preparation require more attention to detail, the results justify the extra effort. Cure times are typically longer than mono-component systems, but the improved performance characteristics make this a popular choice for demanding applications.

Epoxy and Resin-Based Microtopping

Epoxy microtopping and other resin-based systems blend synthetic resins with specialized fillers or function as complete resin finishes. These premium options deliver exceptional chemical and abrasion resistance while maintaining the seamless appearance that makes microtopping so appealing.

They excel in industrial facilities, restaurants, and high-traffic commercial zones where performance demands are highest. However, resin-based systems can yellow under intense UV exposure and typically cost more than cement-based alternatives. Some finishes may also appear less natural than traditional cement surfaces.

Acrylic Pre-Mixed Systems

Acrylic microcements arrive factory pre-mixed and often pre-pigmented for consistent color results across large projects. These systems offer rapid curing, excellent UV stability, and minimal waste, which saves significant time on site while ensuring predictable results.

The convenience factor makes these systems particularly attractive for installers who need reliable outcomes and quick project turnaround. While per-unit costs run higher than powder mixes, the time savings and reduced risk often justify the investment.

| Feature | Mono-Component | Bi-Component | Epoxy/Resin-Based | Acrylic Pre-Mixed |

| Composition | Powder + water | Powder + polymer | Epoxy/synthetic resins + fillers | Factory pre-mixed acrylic |

| Workability | Easy mixing, quick application | Good work time, careful mixing required | Professional handling preferred | Ready-to-use, predictable |

| Durability | Moderate; sealers recommended | High flexibility and adhesion | Very high chemical/abrasion resistance | High UV and stain resistance |

| Cost | Lowest material cost | Mid-range | Highest | Higher per unit, time-saving |

| Best Use | Interior DIY, simple renovations | Minor movement surfaces, wet areas | Industrial, heavy commercial | Fast commercial installs |

Microtopping Application Process, Surface Prep, and Maintenance

Beginning any microtopping project requires thorough surface assessment where technicians evaluate structural integrity, levelness, moisture content, and existing conditions. They repair significant cracks and may install plywood subflooring on wood surfaces to ensure stability and prevent future problems.

Moisture testing helps determine whether vapor barriers or specialized primer systems are necessary for long-term success.

Surface preparation forms the foundation of any successful installation. This comprehensive process includes deep cleaning and mechanical profiling to remove contaminants and create proper surface roughness. Shotblasting or acid etching removes stubborn residues while creating the texture profile needed for optimal adhesion.

High-quality primers or bonding agents from manufacturers like Mapei or Ardex ensure the microtopping material bonds securely to the prepared substrate.

Surface Assessment and Preparation

Before application begins, professionals thoroughly inspect for substrate movement, deep structural cracks, and moisture issues that could compromise the installation. They repair cracks with appropriate epoxy injection systems and fill voids with compatible patch mortars.

For substrates with moisture concerns, they apply specialized primer systems and moisture-resistant formulations to prevent future delamination or performance issues.

After structural repairs, the surface receives thorough cleaning and profiling to ensure primers can penetrate and bond effectively. Following manufacturer specifications for primer application creates the ideal foundation for long-lasting results.

Typical Application Steps

Installation begins with primer or bond coat application to ensure uniform absorption across the entire surface. Base or leveling coats follow to create a perfectly smooth, even substrate that eliminates imperfections before decorative layers begin.

Microtopping application proceeds in multiple thin coats, typically two to three layers applied with steel or plastic trowels to achieve the desired finish character. Each layer must cure properly before light sanding creates the smooth surface needed for subsequent coats.

Color integration and texture development can occur during application or as separate decorative steps. For textured finishes, installers incorporate aggregates like quartz or marble chips. After the final decorative coat cures, protective sealer application provides stain resistance and easy to clean maintenance properties.

Proper cure schedules and final quality inspections ensure the installation meets performance expectations. For wet area applications, complete waterproofing systems and appropriate sealer schedules must be followed before allowing foot traffic.

Maintenance and Repair

Maintaining beautiful microtopping surfaces requires only basic cleaning routines with neutral pH cleaners and prompt attention to spills. Harsh chemicals that can damage protective sealers should be avoided, and furniture protection during moves helps prevent gouges and scratches.

Periodic resealing maintains optimal appearance and protection, with frequency determined by sealer type and traffic levels. Professional contractors can repair minor damage, while more extensive issues may require section replacement.

Using furniture pads and area rugs in high-traffic zones provides additional protection that helps preserve the original appearance for many years.

| Stage | Key Actions | Typical Materials | Importance |

| Assessment | Moisture testing, crack inspection, level verification | Moisture meters, inspection tools | Determines safe installation viability |

| Surface Prep | Cleaning, mechanical profiling, primer application | Shotblast equipment, quality primers | Ensures adhesion, reduces failure risk |

| Base Coats | Leveling, patching, uniform substrate creation | Elastic mortars, cement levelers | Creates even foundation for finish coats |

| Microtopping | Multiple thin coats, sanding between applications | Microcement mixes, pigments, trowels | Builds finish, controls texture and color |

| Sealing | Protective topcoat, cure schedule compliance | Polyurethane, epoxy, or acrylic sealers | Provides stain resistance, easy maintenance |

Installation Cost, Project Factors, and Flooring Comparisons

Microtopping installation costs vary significantly based on system selection and site-specific requirements. In the United States, basic cement-based installations typically range from $3 to $7 per square foot, while premium resin or acrylic systems command higher prices due to their enhanced performance characteristics.

Total project costs depend on material selection, existing substrate condition, desired aesthetic complexity, waterproofing requirements, and regional labor rates. Many projects achieve substantial cost savings because microtopping can be applied directly over existing floors, eliminating expensive demolition and disposal costs.

Compared to other flooring options, microtopping offers compelling value when you factor in longevity and maintenance requirements. It’s important to obtain detailed quotes from qualified installers and consider long-term costs including periodic resealing and expected service life.

Microtopping Pros and Cons

When evaluating microtopping vs traditional flooring materials, several key factors emerge. Microtopping offers seamless, grout-free aesthetics with significantly reduced maintenance compared to tile installations. However, tile systems may provide better options for decorative patterns or extreme heavy-wear applications.

Polished concrete delivers exceptional durability but requires existing concrete slabs as a starting point. Microtopping can achieve similar visual results on virtually any substrate with much less disruption to occupied spaces.

For areas with intense UV exposure, UV-stable acrylic or resin systems prevent color degradation. In environments with chemical exposure or extreme wear, epoxy or resin-based formulations provide superior protection.

| Comparison Factor | Microtopping | Polished Concrete | Tile |

| Substrate Requirements | Any stable surface | Concrete slab only | Stable subfloor required |

| Installation Time | 3-5 days typical | 5-7 days grinding/polishing | 5-10 days including grout cure |

| Maintenance | Easy, no grout cleaning | Periodic resealing required | Grout cleaning, replacement |

| Customization | Unlimited colors/textures | Limited to concrete tones | Pattern/color tile selection |

| Cost Range | $3-12/sq ft | $5-15/sq ft | $8-25/sq ft installed |

Why Terrazzo Granitech Is the Best Microtopping Solution

When selecting a microtopping system for your project, Terrazzo Granitech stands apart as the most advanced and reliable solution available today. Unlike traditional cement-based systems that are prone to cracking and durability issues, Terrazzo Granitech’s patented acrylic resin-based plaster delivers unmatched performance that consistently exceeds industry standards.

The revolutionary anti-crack memory resin technology sets Terrazzo Granitech apart from conventional microtopping materials. While standard cement-based systems often develop hairline cracks and require frequent repairs, Terrazzo Granitech’s advanced formulation maintains structural integrity even on challenging substrates. This superior crack resistance eliminates the callbacks and touch-ups that plague traditional installations, allowing contractors to focus on growing their business rather than revisiting completed projects.

Versatility represents another key advantage of the Terrazzo Granitech system. This innovative material works equally well on walls, floors, ceilings, wet areas, pool decks, and pool interiors—applications where many traditional microtopping products fail or require extensive modifications. The system’s exceptional adhesion properties allow for seamless application over existing mosaic tiles, ceramic surfaces, and even challenging substrates that would typically require complete removal.

The no-demolition, no-permit approach that Terrazzo Granitech enables transforms renovation economics. Property owners save significant money by eliminating demolition costs, waste disposal fees, and permit-related delays. For contractors, this translates to faster project completion and higher profit margins, while clients enjoy minimal disruption to their daily operations.

Environmental responsibility and health considerations make Terrazzo Granitech the smart choice for modern construction projects. The system’s low-VOC formulation ensures healthy indoor air quality, while the reduced demolition requirements significantly decrease construction waste. This sustainable approach aligns with green building practices and LEED certification requirements.

Professional installers consistently report superior working characteristics with Terrazzo Granitech systems. The factory-controlled manufacturing process ensures consistent color and performance across batches, while the user-friendly application properties allow for predictable results even in demanding conditions. Unlike powder-based systems that require precise on-site mixing, Terrazzo Granitech’s pre-engineered formulation eliminates guesswork and reduces installation variables.

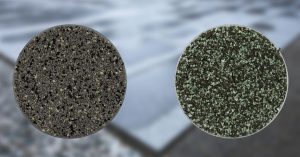

The aesthetic possibilities with Terrazzo Granitech exceed traditional microtopping limitations. The system offers both fine-grain smooth textures for artistic applications and larger-grain formulations for robust, imposing aesthetics. This range allows designers to achieve exactly the visual impact they envision, whether creating subtle elegance or bold architectural statements.

Long-term value distinguishes Terrazzo Granitech from conventional alternatives. While initial material costs may exceed basic cement systems, the extended service life, reduced maintenance requirements, and elimination of crack-related repairs deliver superior return on investment. Professional testimonials consistently highlight the system’s reliability and the peace of mind that comes from using a proven, high-performance solution.

For projects demanding the highest standards of performance, aesthetics, and reliability, Terrazzo Granitech represents the clear choice among microtopping solutions. Its combination of innovative chemistry, proven durability, and exceptional versatility makes it the preferred system for discerning contractors and property owners who refuse to compromise on quality.

Frequently Asked Questions About Microtopping

What is the difference between microtopping and polished concrete?

Microtopping is a thin overlay that can be applied over existing surfaces, while polished concrete requires grinding and polishing an existing concrete slab. Microtopping offers more design flexibility and can be installed on various substrates.

How long does microtopping last?

With proper installation and maintenance, quality microtopping systems typically last 15-25 years. Advanced resin-based systems like Terrazzo Granitech can exceed 30 years with superior crack resistance.

Can microtopping be applied outdoors?

Yes, UV-stable microtopping formulations work excellently for outdoor applications including patios, pool decks, and exterior walls. Choose systems specifically designed for UV exposure.

Is microtopping suitable for bathrooms and wet areas?

Absolutely. When properly sealed and waterproofed, microtopping performs exceptionally well in bathrooms, showers, and other wet areas, providing seamless, easy-to-clean surfaces.

How much does microtopping cost compared to tile?

Microtopping typically costs $3-12 per square foot installed, often less than premium tile installations when you factor in the elimination of demolition and disposal costs.