Did you know that a properly installed resin driveway can increase your property’s value by up to 10%? As these modern surfaces gain popularity across American homes, homeowners face an important choice between epoxy and resin-bound options, each offering distinct advantages in durability, aesthetics, and long-term performance.

Understanding the fundamental differences between these two materials helps you make a confident decision that matches your budget, climate conditions, and maintenance preferences. While both systems provide attractive alternatives to traditional concrete driveway or asphalt surfaces, they differ significantly in composition, installation requirements, and how they handle weather exposure over time.

Table of Contents

Understanding Resin Driveway Systems

Resin bound systems have transformed how homeowners approach driveway design, combining the visual appeal of natural stone with the structural benefits of modern polymer technology. These surfaces work by mixing resin with carefully selected aggregate stones to create a seamless, durable finish that stands up to vehicle traffic while maintaining its appearance for decades.

Definition and Basic Characteristics

A resin driveway combines liquid resin with kiln-dried aggregate stones to form a solid, integrated surface that’s both functional and visually appealing. The resin bound surfacing method involves thoroughly mixing these components before application, which creates tiny voids between stones that allow water to pass through rather than pooling on the surface. This permeability makes resin systems naturally compliant with sustainable urban drainage systems (SUDS) regulations, which many municipalities now require for new driveway installations.

The basic characteristics that define quality resin driveways include exceptional durability that resists cracking and surface degradation, minimal maintenance requirements compared to gravel or block paving, and remarkable aesthetic versatility with dozens of color combinations available. Unlike traditional surfaces that develop weeds between cracks or require regular resealing, a properly installed resin surface maintains its appearance with just occasional cleaning.

Growing Popularity in American Homes

The resin bound system continues gaining traction across American residential properties because it addresses common problems homeowners face with conventional driveway materials. Property owners appreciate how these surfaces manage rainwater runoff effectively, which reduces flood risk in areas prone to heavy precipitation while contributing to more sustainable water management practices.

Beyond practical benefits, resin driveways offer a premium aesthetic that enhances curb appeal without the maintenance headaches associated with loose gravel or the cracking issues common with standard concrete or asphalt installations. The seamless finish eliminates the uneven surfaces and loose stones that plague traditional gravel driveways, while the wide range of colours allows customization that complements any architectural style.

Types of Resin Driveways Explained

Two distinct resin application methods dominate the market, each suited to different priorities, budgets, and performance requirements.

Epoxy Resin Driveways

Epoxy resin driveways create an extremely durable surface through a chemical reaction between epoxy resin and a hardening agent, which bonds strongly to prepared concrete driveway or asphalt bases. This method produces a high-gloss, smooth finish that handles heavy vehicle traffic exceptionally well and resists damage from oil spills, chemical exposure, and harsh weather conditions.

The application process involves coating the prepared base with mixed epoxy resin, then broadcasting aggregate across the wet surface or mixing aggregate directly into the resin before application. When properly installed by experienced driveway contractors, epoxy systems form an impermeable barrier that protects the underlying base from water infiltration. But epoxy does have limitations, including susceptibility to UV degradation that can cause yellowing over time, plus a tendency to crack if the subbase shifts or wasn’t adequately prepared during installation.

Resin-Bound Driveways

Resin-bound driveways take a different approach by premixing resin and aggregates in a forced action mixer before applying the combined material to the prepared surface in a single, integrated layer. This mixing method ensures every stone gets completely coated with resin, which creates a porous structure where water drains through the surface rather than running off or pooling in depressions.

The porous nature of resin-bound systems makes them the preferred choice for properties where drainage systems and water management matter, as they naturally comply with SUDS requirements without additional infrastructure. These surfaces also offer superior aesthetic flexibility since you can blend different aggregate colors and sizes to create custom appearances ranging from subtle earth tones to dramatic contrasts.

Benefits of Installing a Resin Driveway

Modern resin systems deliver a compelling combination of practical performance and visual appeal that traditional materials struggle to match.

Aesthetic Appeal and Wide Range of Colors

Resin driveways stand out for their ability to be fully customized to match or complement your home’s exterior design scheme. With dozens of aggregate options available in a wide range of natural stone colors ranging from warm amber tones to cool grays and everything in between, you can create a distinctive look that reflects your personal taste while enhancing your property’s overall appearance.

The smooth, seamless finish achieves a refined, contemporary aesthetic that looks equally appropriate in front of modern architectural homes or traditional properties where you want to update the curb appeal. You can even combine different aggregate colors in patterns or borders to personalise your driveway design.

Durability and Longevity

Quality resin surfaces deliver impressive longevity when properly installed on a stable base, with many systems lasting up to 25 years or more before requiring replacement. This extended lifespan comes from the resin’s ability to flex slightly with temperature changes rather than cracking like rigid cement-based materials.

The durability advantages include resistance to cracking and surface degradation from freeze-thaw cycles, excellent performance under heavy vehicle loads without developing ruts like gravel or asphalt driveways, and color stability from UV stable resin formulations that prevent the fading common with cheaper alternatives.

Low Maintenance Requirements

One of the most appreciated benefits comes from how easy to maintain these surfaces are compared to alternatives that demand regular attention. You won’t spend weekends pulling weed growth from cracks or redistributing gravel that’s migrated to your lawn, and the smooth surface means a simple rinse with a garden hose keeps it looking fresh without specialized cleaning products.

The low-maintenance nature extends beyond routine cleaning to include minimal driveway repair needs over the surface’s lifetime. Unlike asphalt driveways that require periodic resealing or block paving that may need releveling, properly installed resin systems remain stable with almost no intervention required.

Potential Drawbacks of Resin Surfaces

While resin driveways offer substantial benefits, understanding the challenges helps you make a realistic assessment of whether this solution fits your situation.

Cost Considerations

The most significant barrier for many homeowners comes down to the resin driveway cost, which typically runs considerably higher than conventional materials on a per square foot basis. The premium pricing reflects several factors including the high-quality resin and carefully graded aggregate required, the specialized equipment needed for proper mixing, and the skill level required from installer professionals.

The average cost typically falls between $10 and $20 per square foot for materials and professional installation, though this can vary based on location, the specific aggregate selected, and site preparation requirements. For a standard 1,000-square-foot driveway, you’re looking at a total investment between $10,000 and $20,000.

But you need to consider the total cost of ownership rather than just installation expenses. When you factor in the extended lifespan and minimal maintenance requirements, the long-term value proposition becomes more attractive.

Installation Challenges

Getting a successful resin installation requires more than just purchasing quality materials. The mixing ratios between resin and aggregate must be exact, the weather conditions during application need to fall within specific temperature and humidity ranges, and the preparation of the base surface must meet strict standards. Any shortcuts or mistakes during installation can result in a surface that develops problems like uneven color, premature cracking, or poor drainage within months.

The challenge for homeowners lies in finding experienced contractors who truly understand using resin properly and won’t cut corners. The industry remains largely unregulated, which means anyone can claim expertise without proving qualifications. To avoid problems, thoroughly vet potential contractors by checking references, viewing completed projects in person, and ensuring they have proper insurance.

Epoxy vs Resin-Bound: Key Differences

Choosing between epoxy and resin-bound systems requires understanding how their fundamental differences affect performance and appearance.

Composition and Structure

Epoxy systems work by applying layers of epoxy resin over a prepared concrete or asphalt base, creating an impermeable coating that seals and protects the underlying surface. The resin can be applied as a clear coat with aggregate broadcast into it, or mixed with aggregate before application.

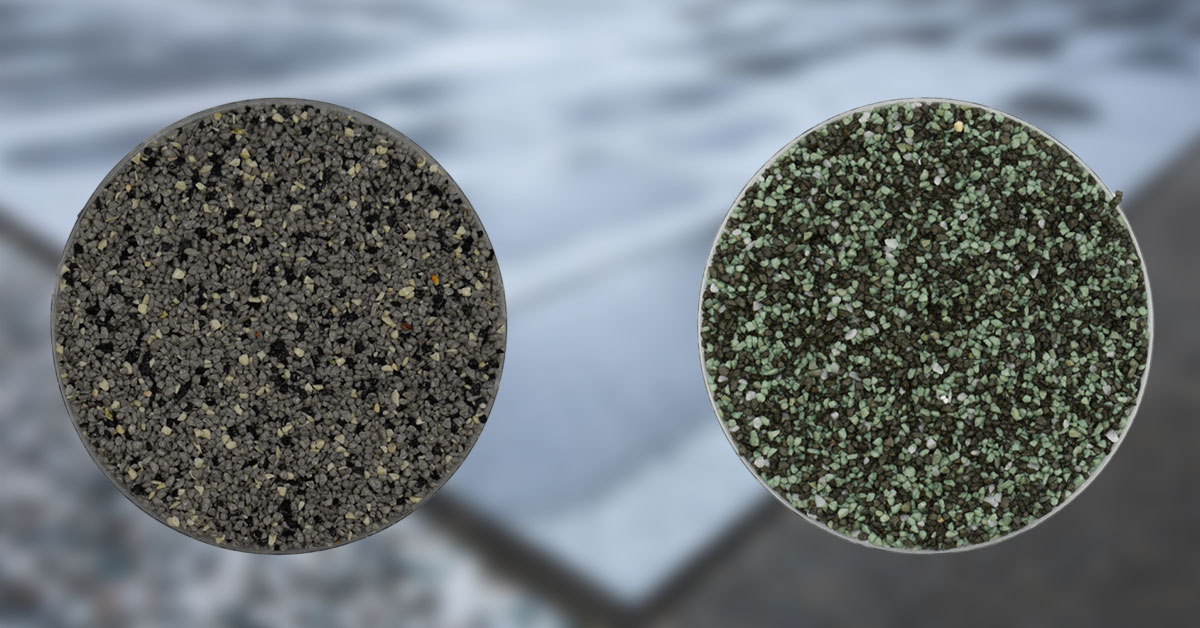

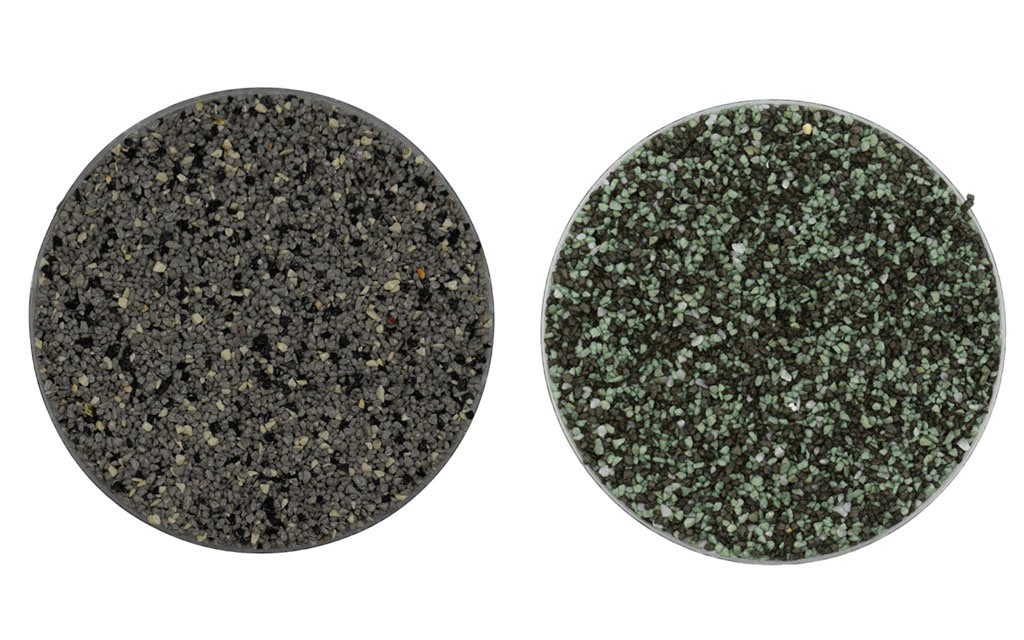

Resin-bound construction differs fundamentally by premixing resin and aggregates used in precise ratios before the material ever touches your driveway. This thorough mixing ensures every stone gets encapsulated in resin, and when troweled onto the surface, it forms an integrated structure with tiny voids between stones that remain open for allowing water to drain through.

Appearance and Finish

The visual differences between these systems are immediately apparent. Epoxy installations typically produce a glossy, uniform appearance where the resin creates a smooth coating, resulting in a wet-look finish that some homeowners love for its modern aesthetic but others find too shiny.

Resin-bound surfaces present a more natural, matte appearance where the aggregate stones remain visible and textured on the surface while being held firmly in place by the resin binder. This creates a look that resembles high-quality exposed aggregate concrete but with a smoother, more refined texture.

Performance in Different Climates

Climate considerations play a crucial role in determining which system performs better for your location. Epoxy’s rigid nature makes it vulnerable to cracking in regions with significant temperature swings, particularly where freeze-thaw cycles stress the material. The impermeable surface also means water runoff concentrates rather than dispersing.

Resin-bound systems handle climate variations more gracefully due to their slight flexibility and permeability. The material expands and contracts with temperature changes without developing stress cracks, and the drainage capability means freeze-thaw damage is minimized. The use of UV stable resin in quality systems prevents the degradation and discoloration that plagues epoxy installations exposed to intense sunlight.

Feature | Epoxy Driveways | Resin-Bound Driveways |

Surface Type | Impermeable coating | Permeable integrated structure |

Appearance | Glossy, uniform finish | Natural, textured look |

Thickness | 3-6mm coating | 15-20mm integrated layer |

UV Resistance | Prone to yellowing | Excellent with UV stable resin |

Drainage | None, water runs off | Full permeability |

Climate Suitability | Limited in extreme conditions | Performs well in varied climates |

Resin Driveway Cost Breakdown

Understanding the complete cost picture helps you budget appropriately and avoid surprises.

Average Pricing per Square Foot

The typical resin driveway cost ranges from $10 to $20 per square foot including materials and labor, though this represents a broad average that can shift based on numerous project-specific factors. Epoxy systems generally fall toward the lower end at $8 to $15 per square foot, while premium resin-bound installations may reach $18 to $25 per square foot in some markets.

For perspective, a modest 500-square-foot driveway would run $5,000 to $10,000, while a larger 1,500-square-foot surface could cost $15,000 to $30,000 depending on the specific system. These figures assume overlay installation on a suitable existing driveway base.

Factors Affecting Installation Costs

Multiple variables influence what you’ll actually pay beyond the basic per-square-foot rate. The choice of aggregate plays a significant role, as premium imported stones cost more than standard local materials. Geographic location matters considerably, with labor rates varying widely between urban and rural areas.

Site conditions and preparation requirements can add thousands to your project budget. If your existing driveway needs repairs, leveling, or drainage improvements before resin application, those preliminary works increase costs substantially. Projects with complex shapes, multiple colors, or borders require more labor, which drives up pricing.

Long-term Value Assessment

When evaluating whether resin driveways justify their premium cost, you need to look beyond the initial investment to the total cost of ownership over the surface’s lifespan. A quality resin installation lasting up to 25 years with minimal maintenance delivers better long-term value than cheaper alternatives requiring frequent repairs or complete replacement every 10 to 15 years.

Consider that asphalt driveways need resealing every 3 to 5 years at several hundred to several thousand dollars per treatment. Concrete driveway surfaces last longer but still crack and stain over time. In contrast, your resin surface investment buys you decades of maintenance-free service with just occasional cleaning required.

The Installation Process for Resin Driveways

Successful laying a resin driveway demands meticulous attention to detail at every stage.

Site Preparation and Subbase Requirements

The foundation of any successful resin installation starts with proper site preparation and a stable subbase. Professional installer teams begin by evaluating your existing base to determine if it’s suitable for overlay or if repairs are necessary.

For overlay installations on existing driveway surfaces, contractors remove all loose material, clean the surface thoroughly, and repair any cracks or unstable areas. The existing surface must be structurally sound and properly sloped for drainage.

New installations require excavating to appropriate depth, installing a compacted aggregate base, and creating a stable platform. The base must be constructed with proper drainage in mind, either incorporating permeable materials or sloped appropriately to direct water off the surface.

Mixing Resin and Aggregates

The mixing stage represents a critical point where precision determines success. Contractors use a forced action mixer because thorough, consistent blending is essential to coat every aggregate particle completely and achieve uniform color throughout the finished surface.

The exact ratio of resin and aggregates varies depending on products being used, but generally falls around 1 part resin to 20 to 25 parts aggregate by weight for resin-bound systems. Installers must measure components carefully and work within the limited window before the resin begins curing.

Application, Curing, and Finishing

Once mixed, the resin and aggregate combination must be applied quickly. Experienced crews spread the material evenly using specialized trowels, working to achieve consistent thickness while maintaining proper surface grade for water drainage.

The trowelled surface gets finished to the desired texture, with workers smoothing and compacting the material to eliminate voids while ensuring the surface remains porous for water passage. Curing time varies based on formulation and weather, but typically the surface can handle foot traffic within 4 to 8 hours to install and light vehicle use within 24 hours.

Maintenance and Care for Your Resin Driveway

Proper maintenance preserves your investment and ensures your surface continues performing optimally.

Routine Cleaning Procedures

Driveways require surprisingly little maintenance compared to alternative materials. Regular sweeping or blowing removes leaves and debris that could stain the surface or block permeable voids.

For more thorough cleaning, a simple rinse with a garden hose removes most surface dirt. Stubborn stains from oil or tire marks can be addressed with mild detergent and water. Pressure washing works well for annual deep cleaning but should be done at moderate pressure settings.

Repairs and Resealing

Quality resin installations rarely need significant driveway repair within their expected service life if properly installed on a stable base. Small areas damaged by heavy impacts can often be patch-repaired using matching materials, though achieving perfect color match can be challenging.

Some manufacturers recommend periodic resealing to refresh the appearance after many years of service, though this represents an optional enhancement rather than a necessary requirement for most installations. If you do choose to reseal your surface, the process involves applying a thin coat of clear resin.

Comparing Resin Driveways to Other Materials

Understanding how resin systems stack up against traditional alternatives helps you evaluate whether the premium cost delivers sufficient value.

Resin vs Concrete and Asphalt

Traditional concrete driveway and asphalt driveways remain popular due to lower initial costs, but they come with significant trade-offs. Concrete offers good strength but presents a plain appearance unless you invest in decorative treatments. The rigid nature makes it prone to cracking as ground shifts, and staining from oil and organic material presents ongoing challenges.

Asphalt costs less initially but requires more frequent maintenance including regular seal coating every few years. The dark surface absorbs heat in summer, and both materials create impermeable surfaces that concentrate stormwater runoff.

Resin surfaces address these shortcomings by offering superior aesthetics, permeability that manages water sustainably, and a maintenance-free service life.

Resin vs Block Paving and Gravel

Block paving delivers excellent aesthetics when properly installed, but individual pavers can shift over time, creating uneven surfaces. The joints between blocks provide pathways for weed growth, and the complex surface collects dirt that’s harder to clean than smooth alternatives.

Gravel driveways offer the lowest initial cost but come with ongoing maintenance burdens. The stones migrate constantly, requiring regular raking, and loose stones track into the house and scatter onto lawns. The unstable surface makes walking uncomfortable and develops ruts from vehicle traffic.

Resin-bound surfaces deliver the attractive appearance of natural stone without the mobility and maintenance problems that make gravel impractical for many properties.

Material | Initial Cost | Lifespan | Maintenance | Permeability | Aesthetics |

Resin Bound | High | 20-25 years | Very Low | Excellent | Highly Customizable |

Epoxy | Medium-High | 10-15 years | Low | None | Modern, Glossy |

Concrete | Medium | 20-30 years | Medium | None | Utilitarian |

Asphalt | Low-Medium | 15-20 years | High | None | Basic |

Block Paving | High | 25+ years | Medium | Limited | Traditional |

Gravel | Low | Indefinite | Very High | Excellent | Natural but Messy |

Environmental Benefits of Permeable Resin Surfaces

Modern construction increasingly demands sustainable solutions that manage water responsibly, making permeable resin systems particularly relevant.

SUDS Compliance and Drainage Solutions

Sustainable urban drainage systems represent a comprehensive approach to managing rainwater that mimics natural infiltration rather than channeling all precipitation into storm sewers. Permeable resin surfaces support these goals by allowing water to pass through the surface and into the underlying soil structure.

The SUDS compliance benefit matters practically because many municipalities now require permeable paving for new driveways or significant renovations. Installing a resin-bound system satisfies these regulations without requiring additional infrastructure like French drains that add complexity and cost.

Beyond regulatory compliance, the water management capabilities deliver real functional benefits. You won’t experience the standing water problems that plague impermeable surfaces after heavy rain, with puddles that create slipping hazards and accelerate freeze-thaw damage.

Reducing Flood Risk and Water Management

The cumulative effect of thousands of impermeable driveways in urban areas dramatically increases flood risk during heavy precipitation. When rain cannot infiltrate where it falls, it concentrates into runoff that overwhelms drainage infrastructure.

Permeable resin installations help mitigate these problems by managing water at the source. Each property that converts to permeable alternatives reduces the burden on community-wide drainage systems and helps preserve the natural water balance. The environmental benefits extend beyond just water management, as permeable surfaces help filter pollutants from rainwater as it passes through.

Why Terrazzo GraniTech Monolith Is the Superior Resin Stone Solution

While traditional resin-bound driveways deliver good performance, Terrazzo GraniTech’s Monolith system represents the next generation of resin stone surfacing technology, engineered specifically to overcome the limitations that plague conventional epoxy and standard resin systems. Monolith uses advanced UV-resistant polyurethane resin rather than epoxy, which eliminates the yellowing, brittleness, and cracking that affect inferior products exposed to sunlight and temperature variations, while its 100% water-permeable structure goes beyond basic SUDS compliance to deliver exceptional drainage performance and superior binder technology that ensures aggregate stones remain locked in place indefinitely without surface degradation or color fading. Installation directly over existing stable bases like concrete or asphalt makes Monolith particularly practical for renovation projects where you want to upgrade your driveway without the expense of complete removal, and if you’re wondering what is resin stone in its most advanced form, Monolith demonstrates how modern materials science creates surfaces that look beautiful while performing flawlessly across all climates. The low-maintenance surface stays clean with minimal care while the flexible, crack-resistant formulation delivers decades of reliable service, making Terrazzo GraniTech Monolith the absolute best choice for homeowners seeking proven performance backed by a company committed to innovation and quality that standard products simply cannot match.