Ever felt lost in a hardware store, unsure about wall finishes? Choosing the right plaster is key for your home’s look and feel. It affects durability, beauty, and comfort.

Plaster does more than just look good. It protects your walls and ceilings from harm. It also supports the structure and can improve insulation and moisture resistance.

Gypsum and cement plasters have their own strengths. One is quick and looks great, while the other is strong and weather-resistant. Knowing these differences is crucial for any building or renovation project.

This guide will help you understand the main differences between gypsum and cement plasters. We’ll look at their makeup, benefits, best uses, and costs. This will help you choose the best plaster for your project.

Key Takeaways

- Plaster provides essential protection and support for both interior and exterior walls

- The right plaster choice depends on your specific application, climate, and budget

- Gypsum-based options typically excel for interior applications with faster drying times

- Cement-based materials offer superior durability for areas exposed to moisture

- Understanding the strengths and limitations of each type ensures optimal results

- Climate conditions in your region should influence your material selection

- Cost considerations include both initial installation and long-term maintenance

Table of Contents

What You Need to Know About Plastering Materials

Plastering materials are key in construction, offering protection, insulation, and beauty to buildings. Knowing the types of plaster and their properties is crucial for any project. It affects both the function and look of your space.

The right plaster choice impacts your walls’ strength and finish. Modern plasters meet various needs, from durability to design. Let’s dive into what makes these materials so versatile.

The Role of Plaster in Modern Construction

In today’s building world, plaster does more than just decorate. Quality plastering adds strength by protecting materials from damage. This makes walls and ceilings last longer.

Plastered walls fight off weather damage like rain and heat. They’re also easy to fix when damaged. Plaster makes surfaces smooth for decoration.

Plaster also makes homes healthier. It traps less dust, cutting down on indoor pollution. Some plasters even help save energy by insulating better.

Plaster is also fire-resistant, thanks to gypsum-based products. This safety feature is vital in buildings everywhere.

Plaster also improves sound quality. Its density reduces noise between rooms. This makes spaces quieter and more peaceful.

Types of Plaster Available in the Market

The market has many plaster types, each for different uses. The main ones are cement-based and gypsum-based plasters. There are also specialized plasters for specific needs.

Gypsum plaster, or plaster of Paris, is made from gypsum. It’s easy to work with, sets fast, and is very smooth. It’s best for inside use where moisture is low.

Cement plaster is strong and water-resistant. It’s great for outside and wet areas like bathrooms. Its durability makes it perfect for tough spots.

Lime plaster is old but still used today. It’s made from lime, sand, and water. Modern lime plasters might include cement for more strength. It’s breathable and fights off germs naturally, and its long-term durability makes it a smart choice for both historic and contemporary applications.

Clay plaster is eco-friendly, made from clay, sand, and fiber. It controls humidity and has a natural look. It’s not common but growing in green building projects.

There are also plasters for sound, heat, and decoration. These specialized plasters meet specific needs beyond just covering walls.

Knowing about these plasters helps choose the right one for your project. The choice between cement and gypsum plasters depends on many factors like location and budget.

Composition and Manufacturing: How Each Plaster is Made

The way gypsum and cement plasters are made affects their properties and uses. Knowing how they’re made helps builders and homeowners choose the right material. Each material has its own production method, affecting how they perform and their environmental impact.

Gypsum Plaster: Extraction and Processing from Gypsum Rock

Gypsum plaster starts with natural gypsum rock, a soft mineral. It’s found worldwide, with big mines in the U.S., Thailand, and Spain.

First, gypsum rock is mined. Then, it’s crushed and ground into smaller pieces. Next, it goes through a heating process called calcination.

In calcination, the rock is heated to 150-180°C (300-356°F). This removes about 75% of its water, turning it into plaster of Paris.

The result is dehydrated plaster powder. This powder is stable until water is added at the site. Then, it sets and hardens. Gypsum plaster is also recyclable, making it sustainable.

Cement Plaster: The Sand-Cement Mixture Process

Cement plaster is made differently. It starts with Portland cement, made by heating limestone and clay at 1450°C (2640°F).

Portland cement production mines limestone, clay, and minerals. These are crushed, ground, and mixed before being heated in a kiln. The heat creates clinker, small, dark gray nodules.

After cooling, the clinker is ground with gypsum to make Portland cement. This cement is the binder in cement plaster.

Cement plaster is made by mixing cement and sand with water at the site. Unlike gypsum, it needs the right mix of cement and sand. The mix ratio is usually 1:4, but can change based on the job.

Mixing must be done right to get the right consistency. Too much water weakens it, too little makes it hard to apply. After mixing, it starts to harden through hydration, a process that takes days or weeks.

Manufacturing Aspect | Gypsum Plaster | Cement Plaster | Environmental Impact |

Raw Materials | Gypsum rock (calcium sulfate dihydrate) | Portland cement, sand, water | Gypsum requires less energy to process |

Processing Temperature | 150-180°C (300-356°F) | 1450°C (2640°F) for cement production | Cement production generates more CO₂ |

Water Requirements | Lower water-to-solid ratio | Higher water requirements | Gypsum is more water-efficient |

Recyclability | Can be recycled multiple times | Limited recycling potential | Gypsum offers better end-of-life options |

The differences in making gypsum and cement plasters explain their unique qualities. Gypsum is lighter and sets faster. Cement is denser and more durable, better for wet areas.

These differences help decide which plaster is best for different building needs. We’ll look at this more in the next sections.

Gypsum Plastering vs Cement Plastering: A Detailed Comparison

Comparing gypsum plaster to cement plaster shows big differences. These differences affect how they’re used and how well they last. Knowing these differences helps you choose the best material for your project.

Setting Time and Curing Requirements

Gypsum plaster sets fast, becoming firm in just 4 hours. This means walls can be ready for painting in 4 days. This is a big advantage for projects with tight deadlines.

Cement plaster takes longer to set, needing 24-36 hours. Walls plastered with cement aren’t ready for painting until 15 days have passed. This is because cement needs time to get strong.

Cement plaster also needs water curing for 7 days. This is to keep it hydrated and strong. Without enough water, it can dry too fast and crack.

Gypsum plaster doesn’t need water curing. It dries naturally and gets strong in about 78 hours. This saves time and water, making it better for the environment.

Weight, Thickness, and Structural Impact

Gypsum plaster is much lighter than cement plaster. It weighs about 1333 kg per cubic meter, while cement weighs 2222 kg. This means gypsum plaster can make buildings lighter, which is good for tall buildings.

Gypsum plaster can be applied in thinner layers, starting at 6mm. Cement plaster needs at least 10mm to be strong. This affects the cost and the size of rooms.

Gypsum plaster has many benefits:

- It puts less strain on buildings

- It can save money on building supports

- It makes rooms slightly bigger

- It’s faster to apply and cheaper to labor

For big projects, these benefits can save a lot of money and time. But, gypsum plaster might not be the best for areas needing extra strength.

Water Resistance and Thermal Properties

Gypsum and cement plaster handle water and heat differently. Cement plaster is better at resisting water, making it great for outside and wet areas like bathrooms.

Gypsum plaster is okay for most rooms but can’t handle water as well. Too much water can make it weak and damaged. But, new water-resistant gypsum is better than old versions.

Gypsum plaster is also better at keeping rooms warm or cool. It has a thermal conductivity of about 0.26 W/mK, while cement is 0.72 W/mK. This means gypsum helps keep rooms at a steady temperature, saving energy.

The table below shows the main differences between gypsum and cement plaster:

Performance Factor | Gypsum Plaster | Cement Plaster | Practical Implication |

Initial Setting Time | 4 hours | 24-36 hours | Faster project completion with gypsum |

Paint-Ready Time | 4 days | 15 days | Quicker finishing schedule with gypsum |

Curing Requirement | No water curing needed | 7 days of water curing | Water conservation with gypsum |

Weight (kg/m³) | 1333 | 2222 | Lower structural load with gypsum |

Minimum Thickness | 6mm | 10mm | Material savings with gypsum |

Water Resistance | Low to Moderate | High | Cement better for wet areas |

Thermal Conductivity (W/mK) | 0.26 | 0.72 | Better insulation with gypsum |

Knowing the differences between gypsum and cement plaster helps you make the right choice. Gypsum is faster and lighter, but cement is stronger in wet areas. The best choice depends on your project’s needs.

Durability Factors: Which Plaster Lasts Longer?

The debate between gypsum and cement plaster often centers on one key point: which lasts longer in real-world settings. When choosing plaster for your home or project, knowing the durability differences is crucial. It helps avoid early repairs or replacements.

Both plaster types have unique traits that impact their lifespan in various settings. Let’s look at the main factors that decide which plaster lasts longer in your situation.

Weather and Moisture Resistance

Cement and gypsum plasters handle moisture and weather differently. Cement plaster is better at resisting moisture, making it great for exterior walls and wet areas. It keeps water out, preventing leaks and moisture-related cracks.

Gypsum plaster, while good at resisting fire, can’t handle moisture well. It absorbs water, leading to damage, softening, and failure in moist conditions. This limits gypsum plaster to dry areas only.

Places with high humidity or water, like bathrooms and basements, should use cement plaster. It’s the best choice for exterior walls facing rain and snow. Cement plaster is essential for weather resistance.

Impact and Crack Resistance Over Time

How well a plaster can handle impacts and resist cracks is key. Cement plaster is harder and more resistant to impacts than gypsum. This makes cement-plastered walls better at withstanding daily wear and tear.

But cement plaster can develop shrinkage cracks during drying. These small cracks can let moisture in if not fixed.

Gypsum plaster, softer and more prone to impacts, is better at avoiding shrinkage cracks. Its flexibility helps it handle minor movements without cracking like cement does.

Durability Factor | Cement Plaster | Gypsum Plaster | Best Choice For |

Moisture Resistance | Excellent | Poor | Cement plaster for wet areas |

Impact Resistance | High | Moderate | Cement plaster for high-traffic areas |

Crack Resistance | Prone to shrinkage cracks | Resistant to shrinkage | Gypsum for areas with minor movements |

Weather Exposure | Can withstand elements | Deteriorates quickly | Cement plaster for exterior applications |

Maintenance Requirements and Longevity

The upkeep needs of your plastered surfaces affect both convenience and cost over time. Cement plaster is more durable and needs less maintenance than gypsum. Once cured and sealed, cement-plastered walls can last decades with little upkeep, mainly in interior settings.

Gypsum plaster doesn’t need extensive curing like cement, which is a plus. But it often requires more care over time, mainly in humid areas. Well-maintained gypsum plaster can last 10-20 years before needing repairs.

When repairs are needed, cement plaster can be harder to fix, needing specialized skills. Gypsum repairs are simpler, making up for its more frequent maintenance needs.

Homeowners should consider cement plaster for tough environments and gypsum for controlled interior spaces. The choice depends on whether you prioritize long life or a balance of durability and easy upkeep.

Aesthetic Appeal and Surface Finish

The look of plaster types is key in making your home beautiful. When picking interior finishes, the wall and ceiling look matters a lot. Gypsum and cement plaster give different looks that affect paint and lighting.

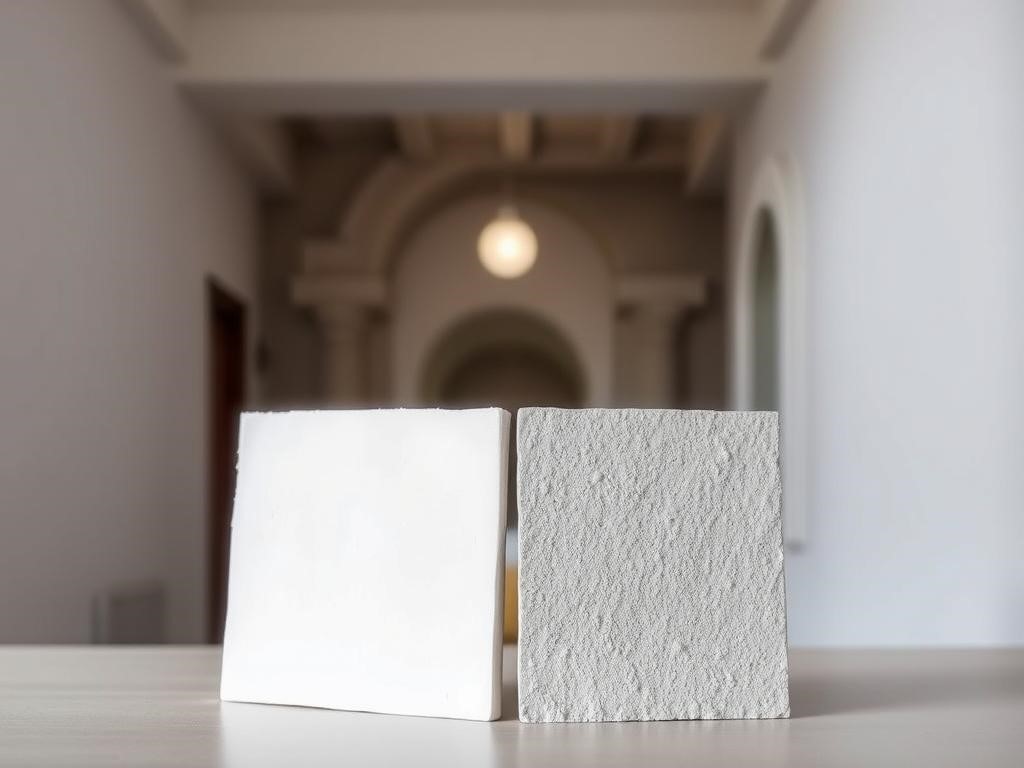

Smoothness and Texture Comparison

Gypsum plaster makes walls and ceilings smooth and refined. It’s perfect for interior designers. Its smoothness is clear to everyone.

Cement plaster, on the other hand, is rough. It has a textured look that can show imperfections and cracks. These flaws affect how nice the walls look.

Gypsum plaster walls are ready for paint without extra work. Their smooth surface takes paint well, giving a professional look.

Cement plaster walls need extra steps before painting. A layer of putty or plaster of paris is needed for a smooth finish. This adds time and cost to the project.

Paint Adhesion and Decorative Possibilities

The look of plaster affects paint adhesion and decoration. Gypsum plaster is best for paint, allowing for good adhesion and color. It also uses less paint and needs fewer coats.

Paint on gypsum plaster lasts longer and looks better. Gypsum’s neutral pH prevents paint problems like discoloration.

Cement plaster, even with putty, may not be as smooth as gypsum. This can cause shadow effects or show surface flaws. Ceilings, in particular, benefit from gypsum’s smoothness.

For fancy finishes like Venetian plaster or textured patterns, gypsum is better. It’s easier to work with and supports detailed designs.

Cement plaster can handle basic decorations but needs more prep for fancy finishes. Its roughness limits some high-end designs or requires extra coatings.

Best Applications for Each Plaster Type

Each plaster type is best for certain projects. Choosing between gypsum and cement plaster affects your project’s look, feel, and durability. Knowing the strengths of each helps pick the best plaster for your building.

Gypsum and cement plasters have unique benefits for different places. Their properties determine where they work best. Let’s look at the best uses for each to help you decide for your project.

Where Gypsum Plaster Excels: Interior Walls and Ceilings

Gypsum plaster is ideal for interior applications where moisture is low. It’s light and has a great finish, perfect for indoor looks. Gypsum outshines cement plaster in many ways when used right.

Living rooms, bedrooms, and dining areas love gypsum plaster. These dry spaces let gypsum show its best. Its smooth finish adds elegance to your design.

Ceilings are a big win for gypsum plaster because it’s light. This means less stress on your building’s structure. It’s safer and more practical for ceilings, which is key in tall buildings.

Gypsum plaster is also great at handling temperature and humidity. It can soak up moisture when it’s humid and release it when it’s dry. This keeps your indoor air comfy and improves air quality.

Home theaters and music rooms benefit from gypsum plaster’s sound-absorbing qualities. It reduces echo and boosts sound quality. This makes it the top choice for audio-focused spaces.

When to Choose Cement Plaster: Exterior and High-Moisture Areas

Cement plaster is a top pick for tough spots where durability and moisture resistance matter. It’s strong and protects exterior walls from weather. When applied right, it acts as a shield against rain, snow, and pollution.

Bathrooms, kitchens, and laundry rooms are perfect for cement plaster. These wet areas need cement’s water resistance and toughness. Cement plaster can handle frequent cleaning and fights mold growth, making it superior to gypsum in wet places.

Basements and foundations need cement plaster’s protective qualities. These areas face ground moisture and water seepage. Cement plaster’s strength keeps the structure solid even in tough conditions.

In extreme weather areas, cement plaster offers needed protection. Its toughness is great for coastal, mountain, or desert environments. It stands up to harsh weather and keeps your building safe.

Places needing lots of drilling for fixtures and fittings also benefit from cement plaster. It’s strong and can hold screws and anchors well. This makes it perfect for kitchen cabinets, heavy shelving, and bathroom fixtures. Your installations will stay secure over time.

Application Area | Recommended Plaster | Key Benefit | Considerations |

Living Rooms | Gypsum Plaster | Smooth finish, better aesthetics | Keep dry, avoid heavy impacts |

Bedrooms | Gypsum Plaster | Temperature regulation, acoustics | Not suitable for humid climates without AC |

Ceilings | Gypsum Plaster | Lightweight, reduced structural load | Avoid in bathrooms or kitchens |

Exterior Walls | Cement Plaster | Weather resistance, durability | Requires proper curing time |

Bathrooms | Cement Plaster | Moisture resistance, mold prevention | Heavier, requires stronger support |

Kitchens | Cement Plaster | Durability, fixture support | Less smooth finish than gypsum |

Basements | Cement Plaster | Water resistance, strength | Longer setting time than gypsum |

When planning your project, think about each space’s needs. The right plaster depends on moisture, temperature, and function. Matching plaster to environment ensures your walls and ceilings last and perform well.

Choosing the Right Plaster for Your Specific Project

Choosing the right plaster depends on several key factors. For exterior walls, cement plaster is best because it’s durable against weather. It can handle rain and humidity well.

For interior spaces, gypsum plaster is often better. It’s lighter and dries faster than cement plaster. This saves time and money since it doesn’t need water curing.

Think about your room’s needs when deciding. Bathrooms and kitchens need cement plaster for moisture resistance. Living rooms and bedrooms look better with gypsum’s smooth finish.

On a budget? One of the disadvantages of gypsum plaster is that it might cost more upfront. Cement plaster is cheaper but needs more finishing work.

Time is also important. Gypsum plaster sets faster, perfect for quick projects. The choice between gypsum and cement depends on your project’s needs.

Climate is another factor. In humid areas, cement plaster is better for water resistance. In controlled environments, gypsum offers better insulation and fire safety.

By considering these factors, you can choose the right plaster for your project. It should balance performance, looks, and budget.

Why Terrazzo GraniTech Is the Ultimate Modern Plaster Solution

While gypsum and cement plasters each offer their strengths, modern construction demands a finish that delivers beauty, performance, and long-term durability, without compromise. That’s where Terrazzo GraniTech comes in.

Terrazzo GraniTech is a patented acrylic resin-based plaster that outperforms traditional gypsum and cement plasters across the board. Designed for both interiors and exteriors, it offers unmatched versatility and aesthetics with stunning terrazzo finishes.

Unlike cement, it doesn’t crack under thermal movement. Unlike gypsum, it thrives in wet environments. Terrazzo GraniTech can be applied directly over tile, wood, cement, or even drywall, saving time and labor with no demolition required.

From luxurious bathrooms to stylish living spaces, GraniTech is redefining what a modern surface finish can be.

Comparison: Terrazzo GraniTech vs Traditional Plasters

Feature | Gypsum Plaster | Cement Plaster | Terrazzo GraniTech |

Water Resistance | Low to Moderate | High | Zero absorption (waterproof) |

Crack Resistance | Good | Moderate (can shrink) | Excellent – adapts to movement |

Surface Aesthetic | Smooth, basic | Coarse, plain | Premium terrazzo-style finish |

Installation Time | Fast | Slow | Fast – applied over existing surfaces |

Suitable for Wet Areas | No | Yes | Yes – ideal for bathrooms & exteriors |

Repair & Maintenance | Easy | Difficult | Seamless spot repairs |

Design Flexibility | Limited | Limited | Customizable, modern textures |

If you’re seeking a durable, waterproof, and design-forward alternative to cement or gypsum, Terrazzo GraniTech is the clear choice. It’s more than a finish. It’s a long-term investment in quality, style, and simplicity.