A thin concrete overlay measuring just 2–3 mm can transform an aging, worn floor into a sleek, modern seamless surface that adds thousands of dollars in property value. Microtopping flooring, sometimes called micro topping or microcement, applies as a remarkably thin layer directly over your existing floors and creates stunning decorative finishes without the mess, expense, and downtime of full demolition.

This comprehensive guide reveals everything you need to know about microtopping systems, from understanding the composition and varieties of microcement to mastering surface preparation techniques and calculating realistic project costs. You’ll discover the practical benefits that make this solution attractive for both residential and commercial spaces, including rapid installation timelines and minimal threshold buildup that preserves door clearances. Whether you’re renovating interior concrete floors or updating commercial environments, this guide provides the real-world information you need to make informed decisions about cement-based overlays versus acrylic or resin systems that deliver superior crack resistance and UV stability, along with guidance on when professional installation becomes essential for achieving durable, long-lasting results.

Principales conclusiones

- Microtopping flooring consists of an ultra-thin recubrimiento de hormigón (2–3 mm) that produces a continuous, grout-free surface over existing substrates

- This versatile system bonds successfully to concrete floors, ceramic tile, masonry, and properly prepared wood surfaces with minimal demolition requirements

- Installation typically completes in 1–5 days, making it practical for time-sensitive residential renovations and commercial projects that can’t afford extended closures

- Cement-based systems and resin or acrylic alternatives each offer distinct advantages for crack resistance, UV stability, and performance in demanding environments

- Strategic finish selection combined with protective sealers ensures both aesthetic flexibility and decades of reliable performance

Índice

What is microtopping flooring and how it’s made

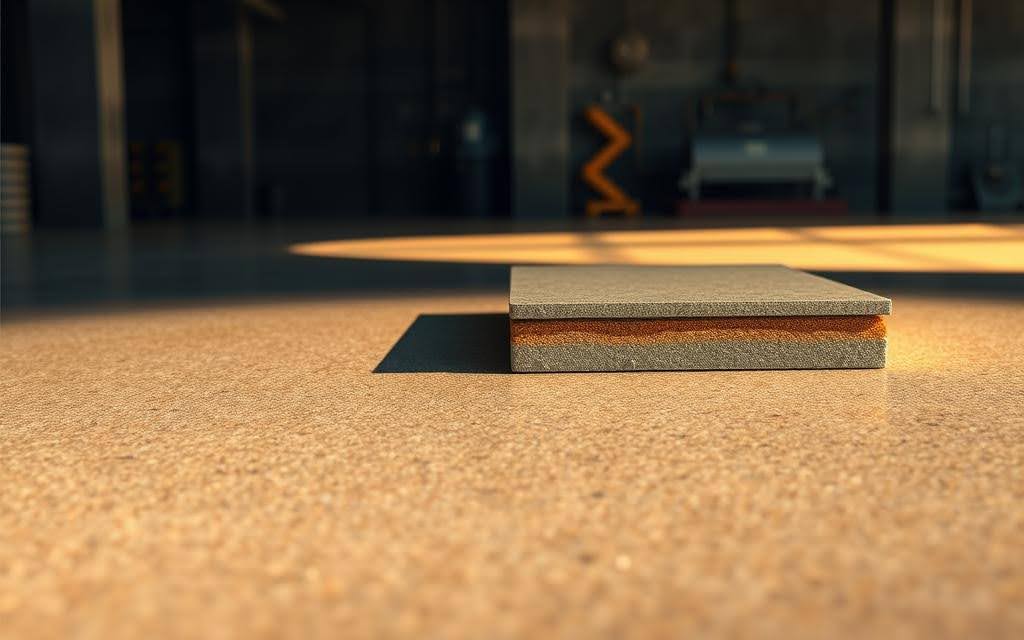

Microtopping represents an innovative thin-layer application method used to refresh and modernize both floors and walls with a suave, uniform finish that typically measures around 2–3 mm in total thickness. The material achieves its distinctive appearance by combining cement with specialized polymer binders that create the seamless look and exceptional adhesion properties that define quality installations.

Definition and core composition

The fundamental mix for microtopping incorporates Portland cement as its structural foundation, blended with fine sand particles and advanced polymers that work together to form a durable, cohesive coating. Portland cement provides the essential base that delivers both compressive strength and reliable bonding characteristics to the underlying substrate, while acrylic polymers or liquid resin additives enhance the mix’s flexibility and tensile strength while simultaneously improving adhesion and reducing the likelihood of cracking under normal stress conditions. Mineral pigments or concentrated liquid colors integrate into the mixture to produce the desired color palette, and protective sealers such as polyurethane, acrylic, or epoxy-based topcoats shield the finished surface from stains while controlling the final sheen level and determining how effectively the floor resists chemicals and moisture penetration over its service life.

Types of systems and material options

Mono-component systems simplify the mixing process by requiring only the addition of clean water on site, making them accessible for DIY enthusiasts and smaller projects, though these formulations typically require additional sealer applications to achieve adequate water resistance and protection against spills. Bi-component systems take a more sophisticated approach by combining cement powder with liquid polymer components during mixing, which significantly enhances adhesion, flexibility, and overall durability while making these products particularly well-suited for high-traffic floors and wet areas where performance demands exceed basic applications. Epoxy-based microtopping formulations represent the premium tier for industrial spaces and commercial environments because they deliver exceptional resistance to both chemical exposure and mechanical abrasion, though these products sometimes develop a yellowish tint over extended periods of UV exposure. Acrylic pre-mixed products offer the convenience of consistent color batching and simplified application procedures that speed up installation timelines, though they command higher per-unit costs compared to site-mixed alternatives. Industry-leading manufacturers such as Mapei and Ardex supply comprehensive primer systems and coordinated product lines, while specialized solutions like Terrazzo GraniTech utilize advanced acrylic resin technology to deliver superior adhesion characteristics and crack-resistant performance that outperforms traditional cement-based alternatives.

Typical substrates and compatibility

Microtopping bonds successfully to an impressive range of substrates including standard concrete slabs, self-leveling underlayments, ceramic tile, traditional terrazzo, and properly prepared wood surfaces, provided the underlying surface maintains sound structural integrity and dimensional stability necessary for lasting adhesion. When working with moist substrates or environments prone to moisture transmission, contractors must install vapor barriers or apply specialized epoxy primers that prevent moisture-related bonding failures and ensure the coating system performs as designed throughout its intended service life. Wood substrates demand additional attention in the form of structural plywood overlayment installed prior to microtopping application, which prevents the flexibility inherent in wood framing from telegraphing through the finish and causing premature delamination, making proper primer selection and appropriate mix formulation absolutely essential for achieving installations that remain intact and attractive for decades rather than failing within months of completion.

Microtopping flooring installation process and surface preparation

The installation journey begins with a meticulous floor assessment where experienced technicians evaluate the substrate’s structural condition, levelness variations, existing crack patterns, and contamination issues while simultaneously conducting moisture testing to identify any dampness concerns that could compromise adhesion. Professional installers check for substrate movement and determine whether specialized reinforcement measures become necessary, then address deep cracks with epoxy injection repairs while filling minor surface imperfections with appropriate patching compounds to establish a stable, level foundation that supports long-term performance.

Surface preparation for optimal adhesion varies based on substrate type and typically involves shotblasting, diamond grinding, or acid etching procedures followed by thorough cleaning protocols that remove all dust, debris, and contaminants that would prevent proper bonding. Reinforcing mesh gets embedded into base coats where additional structural support proves beneficial, and the entire substrate must achieve complete dryness and cleanliness before primer application begins, because any moisture or contamination present during this critical phase inevitably leads to primer delamination and eventual coating failure.

Primer selection depends directly on substrate characteristics and moisture conditions, with specific formulations designed for particular floor types and moisture-blocking primers deployed whenever testing reveals excessive moisture vapor transmission that could damage the coating system. Following manufacturer specifications precisely prevents common installation mistakes that undermine performance, and contractors often apply an additional bonding coat to further enhance adhesion between the primer and subsequent microtopping layers.

The first microtopping layer goes down using steel trowels in smooth, overlapping strokes, with fiberglass mesh reinforcement incorporated into areas prone to movement or stress concentration. After proper curing time elapses, technicians sand the base layer to eliminate trowel marks and create the smooth foundation necessary for subsequent coats to bond properly. The second application consists of a pigmented base coat that builds thickness and introduces color uniformity across the entire surface, which receives light sanding before decorative techniques or final topcoats get applied, and contractors can introduce decorative chips, aggregates, or special texturing methods during this phase to add visual interest and tactile variation.

Final finishing involves careful sanding to remove any surface imperfections or trowel marks, followed by presealer application that prepares the surface for protective topcoats, then at least two coats of durable sealer that provide lasting protection against staining, wear, and moisture penetration. Wet area installations such as those found in bathrooms and kitchens demand full waterproofing membrane systems and extended cure times before the surfaces become ready for regular use and water exposure.

Costs and project factors affecting microtopping flooring price

Understanding the financial investment required for microtopping projects starts with recognizing that basic cement-based systems typically cost between $3 and $7 per square foot for straightforward overlay applications, though prices escalate to $12 or more per square foot when projects incorporate premium materials, complex decorative work, or challenging site conditions. High-end resin or proprietary acrylic systems command $8 to $15+ per square foot including professional installation, reflecting the superior performance characteristics and specialized application expertise these advanced materials require.

Material selection, number of coat applications, and decorative complexity all influence final project costs significantly, as do finishing details such as sealer quality and performance grade, while regional labor rate variations add another layer of cost differentiation that can swing total project expenses substantially depending on local market conditions. Complex design elements or raised threshold edges increase both labor time and material consumption, which directly impacts the bottom line because these features demand additional skilled work and careful attention to detail throughout the installation process.

Choosing to overlay existing tile or terrazzo floors mounted on structurally sound concrete slabs typically saves considerable money by eliminating demolition costs, reducing disposal fees, and shortening overall project timelines that minimize disruption to building occupants or business operations. Conversely, substrates in poor condition necessitate extensive repairs or moisture mitigation systems that increase the total investment required, making thorough pre-installation assessment crucial for accurate budget projections and preventing costly surprises during construction.

Waterproofing specifications and wet-area requirements add measurable expense to projects, particularly when premium resin or acrylic systems get specified for industrial-strength performance and enhanced crack resistance that justify their higher material costs through superior longevity and reduced maintenance expenses. Monochrome finishes using standard cement-based mixes represent the most economical approach, while elaborate multi-tone effects, metallic finishes, or custom aggregate blends push costs toward the upper end of the pricing spectrum.

Factor | Typical Effect on $/sq ft | Performance Notes |

Basic cement microtopping | $3–$7 | Economical material costs, straightforward finish, minimal substrate preparation |

Mid-range decorative systems | $7–$12 | Multiple coat applications, custom color effects, moderate labor intensity |

Premium resin/acrylic systems | $8–$15+ | Exceptional durability characteristics, specialized installation requirements, superior long-term ROI |

Substrate repair and moisture mitigation | +$2–$6+ | Vapor barriers, specialized primers, crack repair work increase total investment |

Demolition cost savings | -$1–$4 per sq ft typical | Avoided disposal fees and reduced installation timeframes lower overall expenses |

Microtopping delivers compelling long-term value propositions that extend far beyond initial installation costs, with cement-based systems regularly achieving 15–25+ year service lives under proper maintenance protocols, while advanced resin formulations routinely exceed 30 years of reliable performance with minimal degradation. Reduced ongoing maintenance requirements and straightforward resealing procedures save substantial money over the floor’s lifetime while boosting overall return on investment, making higher upfront expenditures on premium systems financially justifiable through lower repair frequencies and enhanced property valuations. Smart project planning always factors in long-term value considerations alongside initial costs, recognizing that premium systems often deliver lower total cost of ownership despite commanding higher installation prices, while labor rate variations and installation complexity considerations must inform realistic budget projections and contractor selection decisions.

Benefits, performance, and suitable applications for microtopping

Microtopping excels across diverse residential and commercial applications because it successfully combines practical performance characteristics with design flexibility, creating duradero surfaces that withstand daily wear patterns in both homes and business environments while maintaining the thin profile that makes renovation projects feasible without extensive modifications to existing building elements.

Durability and resistance characteristics

Polymer-modified microtopping formulations demonstrate excellent resistance to abrasion and impact forces, maintaining their integrity under sustained foot traffic and regular cleaning protocols without exhibiting the rapid wear patterns that plague inferior coating systems. When properly sealed using appropriate topcoat products, these surfaces effectively resist staining while preventing liquid penetration that could compromise adhesion or structural integrity beneath the finish layer.

Resin-based and epoxy microtopping variants deliver even more robust performance suitable for demanding industrial floors, busy commercial kitchens, and other environments where chemical exposure and mechanical wear exceed normal residential conditions. Acrylic and specialized resin systems prove particularly valuable for outdoor installations because their formulations resist UV degradation and temperature-induced cracking that quickly destroy cement-only products exposed to weather extremes and direct sunlight.

Expected service life varies considerably based on system type and installation quality, with cement-based options routinely delivering 15 to 25+ years of reliable performance, while high-quality terrazzo-style products incorporating anti-crack resin technology regularly exceed 30 years with minimal maintenance intervention and fewer crack-related failures than traditional cementitious systems experience.

Aesthetic flexibility and customizable finishes

Design possibilities span an impressive range of options, with mineral pigments and liquid colorants enabling virtually unlimited color matching capabilities, while finish selections ranging from high-gloss mirror-like surfaces to matte or heavily textured effects accommodate any aesthetic preference from contemporary minimalism to industrial chic. The seamless application technique eliminates grout lines that visually fragment traditional tile installations, making spaces appear larger and more cohesive while creating the continuous flow that architects and designers prize in modern interiors such as open-concept living rooms, hotel lobbies, and upscale retail environments.

Decorative techniques expand creative possibilities through aggregate incorporation, marbling effects, and specialty texturing or polishing methods that enable designers to craft unique appearances spanning from subtle understated elegance to bold dramatic statements that become defining features of interior spaces.

Wet areas, outdoor use, and specialized solutions

When asking “is microtopping waterproof,” the answer depends on proper waterproofing membrane installation and appropriate sealer selection, which enables successful applications in bathrooms, kitchens, and pool deck environments where moisture exposure occurs regularly. Some specialized microtopping formulations are specifically engineered for pool surrounds and basin interiors, delivering reliable performance in these demanding wet environments when installation protocols are followed precisely and appropriate waterproofing measures are incorporated into the system assembly.

Outdoor formulations incorporate UV-stable pigments and anti-slip surface treatments that make them suitable for terraces, walkways, and exterior patios where weather exposure and traction requirements exceed interior standards. Proper substrate preparation and high-performance sealer application become absolutely critical for maintaining appearance and performance in exterior applications where freeze-thaw cycling, UV exposure, and precipitation create challenging service conditions.

Anti-slip texture options significantly improve safety in wet areas by providing mechanical grip that reduces slip hazards, while projects located near pools or in frequently wet environments absolutely require complete waterproofing system installation and adequate cure time before water exposure begins, ensuring the coating system achieves full strength and moisture resistance before facing operational demands.

Environmental and practical advantages

The thin profile characteristic of microtopping translates directly into reduced material consumption and minimized waste generation compared to traditional flooring replacement approaches, while the ability to aplicar directly over existing substrates eliminates demolition waste and disposal costs while substantially reducing project-related environmental impacts. Low-VOC formulations support healthy indoor air quality objectives and contribute toward green building certification requirements, while faster installation timelines and reduced permit requirements further diminish environmental footprints compared to complete tear-out and replacement approaches that generate substantial waste streams and consume excessive resources.

Característica | Primary Benefit | Optimal Applications |

Exceptional durability and abrasion resistance | Extended service life under heavy traffic conditions | Commercial environments, high-traffic corridors, industrial facilities |

Impact and chemical resistance | Maintains surface integrity in demanding conditions | Restaurant kitchens, retail spaces, manufacturing operations |

Waterproof and stain-resistant characteristics | Prevents moisture ingress while simplifying cleaning protocols | Bathrooms, pool decks, commercial kitchens |

Slip-resistant surface options | Enhances safety where wet conditions regularly occur | Pool perimeters, exterior terraces, commercial restrooms |

Customizable aesthetic finishes | Broad design spectrum from subtle matte to dramatic high-gloss | Showrooms, hotel lobbies, contemporary living spaces |

Thin profile with minimal environmental impact | Reduces material waste while shortening installation duration | Renovation projects over existing floors, sustainable building initiatives |

Maintenance, common issues, and how microtopping compares to other floors

Microtopping surfaces remain relatively easy to maintain through simple daily cleaning routines, though they do require periodic attention to preserve their protective sealer systems and maintain optimal appearance throughout their service lives. Regular sweeping or vacuuming removes abrasive particles, while damp mopping with pH-neutral cleaning solutions keeps sealers functioning properly without degrading their protective capabilities, and prompt spill cleanup prevents staining compounds from penetrating the sealer layer and discoloring the underlying microtopping.

Furniture pads and area rugs in high-wear zones protect against scratches and gouges from chair legs and heavy furniture movement, while the protective topcoat requires resealing every 1–6 years depending on traffic intensity and wear patterns, with residential installations typically falling at the longer end of this range compared to commercial sites experiencing constant foot traffic and cleaning protocols. Most microtopping problems originate from substrate issues or improper application techniques rather than inherent finish deficiencies, and concerns about microcement cracking usually trace back to inadequate substrate stabilization or movement accommodation rather than coating formulation defects.

Delamination failures almost always result from inadequate surface profiling or incorrect primer selection during installation, requiring removal of failed material followed by proper re-profiling and application of appropriate primer systems before reinstallation can proceed. Stains and worn sealers respond well to thorough cleaning followed by fresh topcoat application, though deeper damage may necessitate localized repair or section replacement, and moisture-related issues demand comprehensive testing followed by vapor-blocking primer installation before repairs can succeed long-term.

When comparing microtopping vs tile flooring, microtopping delivers seamless, grout-free surfaces that drastically simplify cleaning routines and eliminate the time-consuming grout maintenance that tile installations demand, though tile may prove superior for extremely heavy-duty applications or situations requiring bold geometric patterns that only individual tile units can achieve. The comparison between microcement vs microtopping reveals these terms are often used interchangeably, though microcement sometimes refers specifically to cement-based systems while microtopping can encompass resin-based alternatives as well.

Microtopping proves far less invasive than polished concrete installations because polished concrete demands extensive grinding operations using heavy machinery that may be impractical in occupied buildings, whereas microtopping applies over existing floors without requiring structural concrete exposure or intensive mechanical surface preparation. When evaluating microtopping vs epoxy flooring options, microtopping offers more diverse aesthetic possibilities and works better where natural cement appearance is desired, while epoxy delivers superior chemical resistance and works better in industrial settings with severe exposure conditions, though epoxy often exhibits less design flexibility and may yellow under UV exposure over time.

Compared to traditional terrazzo or advanced resin systems, standard microtopping performs admirably in residential and light commercial applications but may not match the extreme durability and crack resistance that premium alternatives deliver, particularly in exterior locations with direct sun exposure or areas subject to significant structural movement. These high-performance alternatives typically last longer with fewer maintenance interventions but command substantially higher initial investments, making microtopping the practical choice when project priorities emphasize seamless customizable finishes over existing floors, straightforward cleaning requirements, and reasonable maintenance demands rather than absolute maximum performance in extreme conditions.

For projects involving significant moisture concerns, exterior exposure, or intense commercial traffic patterns, consultation with experienced contractors becomes essential to ensure appropriate system selection, proper primer specification, and realistic resealing schedule development that collectively ensure your floor performs reliably and remains economically repairable when normal wear and tear eventually demands attention.

Microtopping in bathroom applications and specialized environments

Understanding the pros and cons of microcement bathroom installations requires examining both the compelling benefits and realistic limitations these systems present in wet environments. The advantages of microtopping in bathroom settings include the seamless, grout-free appearance that eliminates moisture-trapping grout lines where mold and mildew typically accumulate, combined with the ability to create visually spacious environments through uninterrupted surfaces that flow from floor to wall without breaks or transitions. When properly waterproofed and sealed, these installations resist moisture penetration while providing easy-to-clean surfaces that maintain their appearance through years of daily use and humidity exposure.

However, the microcemento baño pros y contras discussion must also acknowledge that cement-based systems require meticulous waterproofing membrane installation beneath the finish coat to prevent moisture infiltration that could compromise adhesion or damage underlying substrates, and regular resealing becomes necessary to maintain moisture resistance as protective topcoats gradually wear under cleaning protocols and water exposure. Proper ventilation remains essential to minimize standing moisture and condensation that can eventually penetrate even well-sealed surfaces, while substrate movement from building settling or temperature fluctuations poses greater risks in wet areas where compromised sealers allow moisture to reach vulnerable bond lines.

Why Terrazzo GraniTech represents the ultimate microtopping solution

Terrazzo GraniTech has fundamentally reimagined what microtopping can achieve by replacing traditional cement-based formulations with a revolutionary granite and acrylic resin-based plaster that eliminates the primary weaknesses that plague conventional systems. Unlike cement-based microtopping products that remain vulnerable to cracking from substrate movement and thermal stress, GraniTech’s patented anti-crack memory resin technology absorbs stress and movement without developing the hairline fissures that compromise both appearance and performance in traditional installations, making it the superior choice for both new construction and demanding renovation projects.

This advanced resin-based system installs successfully over virtually any surface including existing mosaic tiles, ceramic, and even challenging substrates that would require extensive demolition using conventional methods, delivering significant cost savings by eliminating tear-out expenses and permit delays while preserving existing building elements. The material’s exceptional durability and crack resistance stem from its sophisticated acrylic resin matrix that outperforms cement-based alternatives in wet areas, pool applications, and high-traffic commercial environments, consistently delivering flawless results without the callbacks, touch-ups, and premature failures that burden contractors working with inferior products. Terrazzo GraniTech’s proven performance in both interior and exterior applications, combined with its seamless jointless finish that resists discoloration and maintains structural integrity even under demanding conditions, establishes it as the definitive solution for professionals and property owners who refuse to compromise on long-term performance and aesthetic excellence.