Could a permeable driveway be the smart, eco-friendly option that both saves your yard from water damage and reduces stormwater headaches while adding real value to your property? This guide explains why permeable paving has become increasingly popular across the United States, showing you exactly how these innovative driveways allow water to soak naturally into the ground instead of running off into streets and storm drains, which means less pollution, better groundwater recharge, and surprising design flexibility that most homeowners don’t realize is possible.

Throughout this article, readers will learn about realistic cost ranges that span everything from budget-friendly plastic grid systems to premium pervious concrete installations, and we’ll discuss the specific factors that affect pricing while showing you how to ensure long-term performance without breaking the bank. Our goal is to help homeowners make an informed decision about whether a permeable driveway is the right choice for their specific property, climate, and budget.

Principales conclusiones

Permeable driveways allow water to pass through or between materials, which dramatically reduces stormwater runoff while naturally recharging groundwater supplies beneath your property. Costs vary significantly based on material choice, with simple grid systems offering the most affordable entry point while pervious concrete and decorative pavers require higher upfront investment but deliver superior longevity and aesthetics.

Material selection, proper base design, and professional instalación are absolutely critical to ensuring your driveway performs well for decades rather than failing within a few years. Routine mantenimiento that includes sweeping, vacuuming joints, and occasional stone replenishment keeps permeability high and prevents the clogging issues that plague neglected permeable surfaces.

Índice

What is a permeable driveway and how it works

A permeable driveway lets rainwater soak through its surface rather than running off into gutters and streets, and it accomplishes this through wider joints between pavers or specially engineered concrete mixes that create connected pores for water infiltration. Beneath the visible surface sits a substantial base layer of crushed stone, typically 6 to 18 inches thick depending on soil conditions and expected vehicle loads, which temporarily stores stormwater before it gradually infiltrates into the native soil below.

This intelligent design serves multiple purposes at once, supporting vehicle weight while promoting natural drenaje patterns that mimic how undeveloped land handles rainfall. The system works by allowing water to enter through the surface, filter through the joints or porous material, and collect temporarily in the stone reservoir where sediment settles out and beneficial microbes break down common pollutants like oil residues and heavy metals.

Comparison with traditional concrete and asphalt driveways

Traditional concrete and asphalt driveways create impermeable surfaces that channel 100% of rainfall toward gutters, storm drains, and eventually local waterways where it carries pollutants and contributes to flooding problems. In contrast, permeable systems reduce or eliminate this stormwater runoff depending on the design, which means less strain on municipal infrastructure and dramatically lower pollutant loads reaching rivers and streams.

Pervious concrete and porous asphalt look remarkably similar to their conventional counterparts from a distance, but their internal structure allows water to pass through while maintaining the strength needed for vehicle traffic. Permeable pavers offer even more design flexibility with patterns, colors, and textures that standard asphalt simply cannot match, which makes them an attractive option for homeowners who refuse to compromise aesthetics for functionality.

Environmental benefits and practical advantages

Permeable pavement delivers impressive beneficios medioambientales that extend well beyond basic water management, including significant reductions in pollutants reaching local waterways, effective erosion control through slowed water velocity, and meaningful contributions to groundwater recharge that support wells and baseflow in nearby streams. These systems also reduce standing water and ice formation, which means you’ll use less winter salt and chemicals, and permeable surfaces stay noticeably cooler than dark asphalt because they don’t absorb and radiate heat the same way, helping to mitigate urban heat island effects in your neighborhood.

Types of permeable materials and paver options

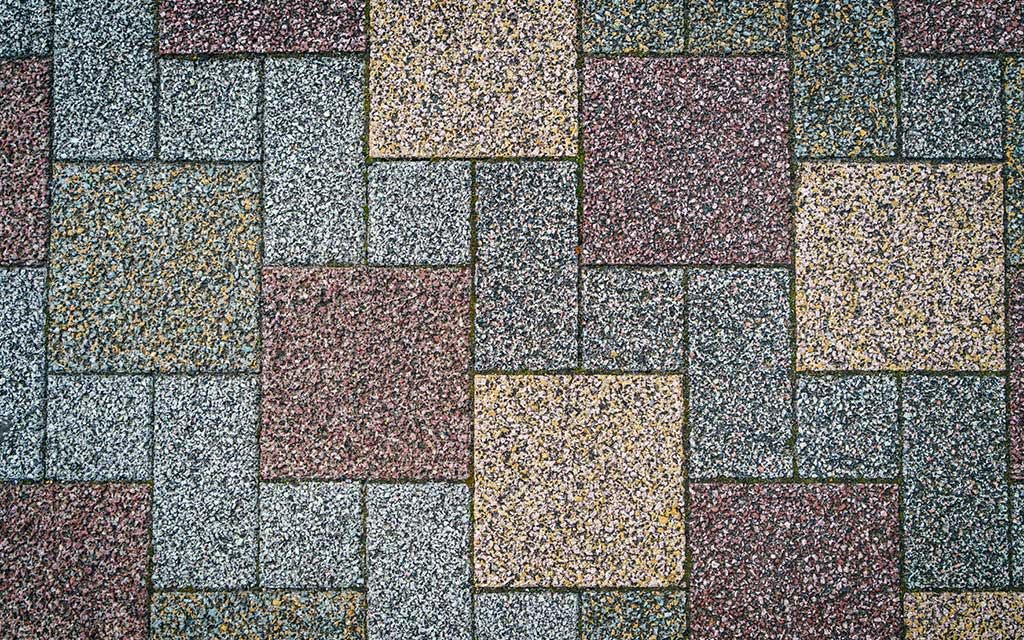

The market offers numerous permeable materials suitable for driveways, walkways, parking areas, and patios, with each option presenting distinct advantages depending on expected vehicle loads, desired appearance, maintenance willingness, and site-specific drainage characteristics. Your choice will significantly affect how effectively your property manages stormwater and how well the finished surface complements your home’s architectural style.

Permeable pavers include interlocking concrete pavers, traditional brick units, and modern composite tiles, all designed with wider joints that allow water to pass through into the crushed stone base below. Concrete pavers are exceptionally durable and available in dozens of shapes, colors, and textures, while composite pavers mimic natural stone appearance but weigh less and handle more easily during installation and future repairs.

Concrete grid pavers feature structural ribs that create stable cells for gravel or turf infill, resisting heavy loads while keeping the gaps open and functional for decades. Plastic grid systems represent the most budget-friendly option and work beautifully with grass pavers or decorative stone infill, with grass creating a green appearance that absorbs runoff naturally but requires regular mowing and occasional topdressing with soil or additional stone to maintain proper levels.

Poured permeable surfaces and resin options

Pervious concrete and porous asphalt form continuous surfaces with interconnected voids throughout their structure, similar to looking at a rice crispy treat where you can see the spaces between cereal pieces. Pervious concrete typically lasts longer under heavy loads and resists freeze-thaw damage better in cold climates, while porous asphalt installs faster and can prove more economical for larger commercial areas or municipal projects.

Both materials require a deep, carefully graded base and installation crews specifically trained in working with these specialized porous mixes. Understanding what is resin stone opens up additional possibilities, particularly resin bound gravel surfaces that mix decorative aggregate with UV-stable polyurethane binders to create smooth, porous finishes with excellent traction and extensive color choices.

A resin driveway differs significantly from resin-bonded options because resin-bound systems mix the resin throughout the aggregate for true permeability, while bonded versions simply sprinkle loose stones onto a resin surface coat and don’t allow water infiltration. Quality gravel binder resins with UV stabilization help ensure longevity and minimize the color fading that plagued earlier epoxy-based systems, making modern resin-bound surfaces a competitive option for homeowners seeking distinctive aesthetics with environmental responsibility.

|

Permeable Material Type |

Typical Cost (per sq ft) |

Main Benefits |

Requisitos de mantenimiento |

|

Concrete interlocking pavers |

$10 – $40 |

Durable, extensive style options, strong drainage with joint stone |

Sweep joints, refill gravel annually |

|

Concrete grid pavers |

$4 – $12 |

High load capacity, stable surface for vehicles |

Occasional joint stone replacement |

|

Plastic grid / grass pavers |

$5 – $10 |

Low material cost, eco-friendly appearance |

Mow turf, refill infill as needed |

|

Pervious concrete |

$6 – $15 |

Strong, continuous porous surface |

Specialized repair, vacuum cleaning |

|

Porous asphalt |

$6 – $15 |

Fast installation, economical for large areas |

May require more frequent resurfacing |

|

Resin-bound surfaces |

$15 – $35 |

Decorative, smooth, excellent traction |

Keep clean, protect from oil stains |

Permeable driveway cost breakdown and budgeting

National cost ranges for permeable driveway projects vary dramatically based on material selection and site complexity, with basic options like plastic grass grids or concrete grid systems at the low end around $5 to $12 per square foot installed, midrange choices including interlocking permeable pavers and resin-bound surfaces running $10 to $30 per square foot, and high-end selections featuring natural stone or complex grading pushing costs toward $25 to $40 per square foot or higher.

For a typical 640 square foot two-car driveway, total project costs generally range from approximately $4,800 for basic DIY-friendly systems with homeowner-completed prep work to $33,600 or more for premium materials installed by experienced contractors on challenging sites. Material costs represent only part of the equation, with labor typically consuming 40% to 60% of your total budget depending on excavation requirements, base depth, and installation complexity.

Labor, base materials, and additional costs

Professional labor rates for permeable paving installation run between $5 and $15 per square foot, influenced heavily by project complexity, site accessibility, and contractor experience with these specialized systems. A proper sub-base requires substantial quantities of crushed angular gravel in 6 to 18 inch depths, with material costs around $40 to $86 per cubic yard, and thicker bases combined with increased material hauling distances can add $1 to $4 per square foot to your project costs beyond the basic estimates.

Permits, site preparation, and existing driveway demolition contribute additional expenses that catch many homeowners by surprise, with permits typically costing $50 to $250 depending on your municipality, site grading and preparation running $1 to $2 per square foot for minor work or $1,000 to $3,300 for significant regrading projects, and old driveway removal adding $1 to $3 per square foot before the new installation even begins. Specialized installation techniques required for pervious concrete or porous asphalt often increase contractor fees because these materials demand specific equipment and trained crews who understand the critical mixing and compaction requirements.

Practical cost-saving strategies

Smart homeowners can manage their permeable driveway budget by choosing concrete pavers over premium natural stone, obtaining multiple detailed bids from contractors with verified permeable paving experience, phasing work across different seasons to spread costs, and taking on permitted preparation tasks like excavation or old driveway removal to reduce professional labor charges. Always confirm local permit requirements and schedule inspections early in your planning process to avoid surprise fees or project delays that increase costs when crews sit idle waiting for approval.

|

Budget Component |

Typical Cost Range |

Important Notes |

|

Plastic grass pavers (material) |

$5 – $10 / sq ft |

Lower material cost; total installed price higher with labor |

|

Concrete grid pavers (installed) |

$4 – $12 / sq ft |

Popular choice balancing price and durability |

|

Permeable/interlocking pavers |

$10 – $40 / sq ft |

Wide range covers basic concrete to premium stone |

|

Pervious asphalt/concrete |

$6 – $15 / sq ft |

Requires skilled crews and specialized equipment |

|

Resin-bound surfaces |

$15 – $35 / sq ft |

Decorative, permeable, smooth finish |

|

Professional labor |

$5 – $15 / sq ft |

Varies with complexity; often half of total cost |

|

Base materials (sub-base) |

$1 – $4 / sq ft additional |

Depends on depth, hauling distance, stone type |

|

Permits & site preparation |

$50 – $3,300 |

Small permits to major regrading or removals |

|

Two-car driveway examples |

Low: $4,800 – $8,000<br>Mid: $8,000 – $18,000<br>High: $18,000 – $33,600+ |

Reflects material choice, labor, site complexity |

Installation process and critical success factors

Successful permeable paving projects begin with thorough site assessment that tests soil permeability, identifies underground utilities, checks local building codes and stormwater regulations, and evaluates proper slopes for drainage before any excavation begins. A qualified contractor or landscape architect will perform these evaluations to avoid expensive delays and ensure your investment performs as expected for decades rather than failing within a few years due to poor planning.

Excavation depth depends entirely on your soil type and its natural infiltration capacity, typically starting at 15 inches minimum for driveway applications but often requiring 18 to 24 inches or more in areas with clay soils or high water tables. The crushed stone base uses a layered design with larger angular stone at the bottom for structural support and water storage, progressively smaller stone in middle layers for load distribution, and a final bedding layer of 1/4 inch stone that provides a stable, level surface for paver placement.

When laying permeable pavers, experienced installers start at the lowest corner of the driveway and work upward following natural drainage slopes, keeping pavers tight against edge restraints while maintaining the manufacturer-specified joint widths that allow proper water infiltration. Specialized spacers built into many modern permeable pavers automatically create correct gaps, and any edge cuts require a wet-blade concrete saw to achieve clean lines without cracking the units.

Edge restraints represent one of the most critical components that homeowners and inexperienced contractors often underestimate, because these concrete or heavy-duty plastic borders prevent lateral paver movement under vehicle loads that would otherwise cause joint widening, surface unevenness, and eventual failure. Pervious concrete and porous asphalt installations demand even more specialized knowledge, using specific concrete mixers, rollers, and compaction equipment while carefully managing the aggregate-to-cement ratio and water content to achieve strength without closing off the pores that enable infiltration.

Site preparation and base construction

Remember to call 811 at least two business days before beginning any excavation to have underground utilities marked, measure your material needs carefully with 10% overage to avoid mid-project shortages, and plan for temporary stockpiling areas for excavated soil and incoming stone deliveries. Properties with poor native soil drainage or regions experiencing frequent heavy rainfall may require additional underdrain pipes or deeper reservoir layers beyond the standard specifications, which your contractor should identify during the initial site assessment and include in your project estimate.

Professional crews working on favorable sites typically complete a standard two-car driveway installation in approximately three days assuming good weather, though complex grading, difficult access, or wet conditions can extend this timeline significantly. The combination of proper site assessment, correct excavation depth, quality angular stone, careful bedding preparation, and thorough compaction at each layer creates permeable driveways that perform reliably for 20 to 30 years or longer with appropriate maintenance.

Design options and functional planning

Thoughtful layout planning connects curb appeal directly to long-term performance, allowing homeowners to select paver patterns and materials that complement their home’s architectural style while also addressing practical concerns like drainage slope management, driveway dimensions appropriate for expected vehicle sizes, and phasing options that spread costs across multiple budget cycles. Pattern choices range from traditional running bond and herringbone designs that create visual interest to modern grid patterns with grass or gravel infill that soften the hardscape appearance.

Grass pavers and decorative gravel infill offer particularly attractive options for homeowners seeking a softer, more natural aesthetic that blends hardscape functionality with landscape character. Concrete or plastic grass grids filled with turf create genuinely green driveways that still support vehicle weight, though this approach requires regular mowing, irrigation during dry periods, and occasional overseeding to maintain appearance.

Gravel-filled systems prove more economical and lower maintenance than grass options but may need stone replenishment after harsh winters with repeated freeze-thaw cycles and snowplow damage. Integrating your permeable driveway with a comprehensive property drainage system through thoughtful landscape grading ensures water flows evenly into the base rather than concentrating in problem areas that cause erosion or overwhelm the system’s capacity.

Maintenance, common issues, and repairs

Permeable driveways require consistent maintenance to preserve their water infiltration capacity and structural integrity, but a straightforward annual care plan prevents the vast majority of problems while keeping your investment performing like new for decades. Regular attention costs far less than neglect followed by major repairs or premature replacement that could have been easily avoided with basic upkeep.

Clear loose debris from the surface at least twice yearly using leaf blowers, stiff brooms, or shop vacuums to prevent organic material from clogging joints and reducing infiltration rates. Annual or biannual pressure washing with specialized vacuum recovery equipment removes fine sediment that accumulates deep in joints, with some contractors offering this service for $0.25 to $0.50 per square foot, though homeowners can rent appropriate equipment from tool rental centers for $50 to $100 daily if they prefer DIY approaches.

Weed control stays manageable through hand-pulling when weeds are small or applying eco-friendly herbicides specifically labeled for use around permeable paving, avoiding products that could harm soil microbes or groundwater. After heavy rainstorms or extended periods of traffic, inspect joint stone levels and replenish with matching 1/4 inch angular stone as needed to maintain proper spacing, which prevents paver edges from chipping and preserves infiltration capacity.

Troubleshooting drainage and structural issues

Standing water or slow infiltration typically indicates clogged joints packed with fine sediment or organic debris, so begin troubleshooting with thorough surface cleaning and joint vacuuming before assuming more serious problems. Persistent drainage issues after cleaning may signal base layer clogging from sediment intrusion through inadequate geotextile fabric, compacted native soil beneath the installation, or insufficient base depth for your soil type, all of which require professional assessment and potentially significant remediation work including partial excavation and base replacement.

Uneven surfaces and paver shifting usually trace back to inadequate base preparation, failed edge restraints that allow lateral movement, or vehicle overloading beyond the system’s design capacity. Correcting these problems requires removing affected pavers, evaluating and releveling the base layers with fresh compaction, reinstalling the pavers carefully, and inspecting or replacing edge restraints that show signs of damage or movement before problems spread throughout the driveway.

Benefits, drawbacks, and decision factors

Permeable driveways deliver meaningful environmental benefits including dramatically reduced stormwater runoff that protects local waterways, effective pollutant filtering that removes oils and heavy metals before they reach streams, erosion control through distributed infiltration, groundwater recharge that supports aquifers and well water supplies, reduced winter ice formation that cuts chemical and salt usage, and noticeably cooler surface temperatures compared to asphalt that help mitigate urban heat island effects while creating more comfortable outdoor spaces during summer months.

However, these advantages come with higher upfront costs than conventional asphalt or concrete, typically 20% to 50% more expensive for comparable square footage, and permeable systems require more active maintenance including regular joint cleaning, stone replenishment, and occasional professional vacuum services to maintain infiltration capacity. Properties with poor native soil infiltration, high water tables, or heavy clay soils may need additional engineering including deeper bases, underdrain systems, or hybrid designs that partially discharge to storm sewers, all of which increase complexity and cost beyond standard installations.

Homeowners considering permeable driveways should evaluate several critical factors including soil percolation test results that indicate natural drainage capacity, local climate patterns including typical rainfall intensity and freeze-thaw cycles, planned driveway dimensions and expected vehicle weights, realistic maintenance commitment and budget for ongoing care, local regulatory requirements and potential incentives or stormwater fee reductions, and long-term value considerations including property value enhancement and avoided costs for traditional drainage infrastructure.

Starting your project with detailed quotes from multiple licensed, insured contractors who specialize in permeable paving gives you realistic cost expectations and allows comparison of approaches, material recommendations, and warranty coverage. Check contractor credentials carefully including licenses, insurance certificates, manufacturer certifications for specific paver systems, and references from recent projects you can inspect personally, because installation quality makes the difference between decades of trouble-free performance and expensive repairs within just a few years.

Why choose Terrazzo Granitech’s Monolith for your permeable driveway

When you’re ready to move beyond traditional permeable paving options, Terrazzo Granitech’s Monolith system represents the next generation of water-permeable surfacing technology designed specifically for driveways, patios, pool decks, and high-traffic exterior applications. Monolith delivers 100% permeability through a UV-resistant polyurethane piedra de resina system that installs directly over stable existing bases like concrete or asphalt, eliminating the costly excavation and base construction required by conventional permeable pavers.

Unlike inferior epoxy-based systems that crack, yellow, and fail under UV exposure, Monolith’s advanced polyurethane binder technology provides exceptional flexibility, superior durability, and long-lasting color stability even in harsh climates and full sun exposure. The system allows complete water infiltration while creating a seamless, attractive surface available in multiple designer color blends from deep obsidian black to warm amber tones, giving you permeable performance without sacrificing aesthetics.